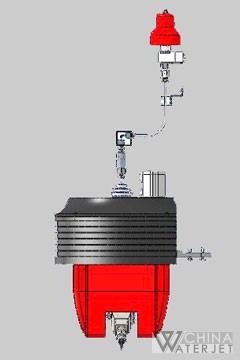

5-Axis Waterjet Cutting System

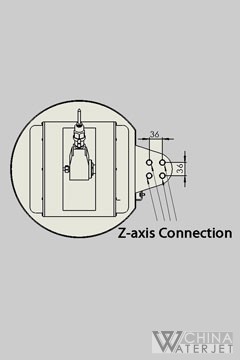

High pressure water switch can quickly shut off high pressure water to save energy. High pressure water can get into cutting head through high pressure pipe, and then get into high precision cutting head body through gem nozzle. Abrasive can get into high precision cutting head body through abrasive transport pipe. Abrasive-water mixture is sprayed onto the materials to be processed through abrasive pipe for cutting purpose. The so-called 5-Axis Waterjet Cutting System refers to the minimum five coordinates axes (three linear coordinates and two rotary coordinates) set on a numerically-controlled ultra high pressure water cutting machine, which can also, under the control of computer numerical control (CNC) system, conduct coordinated movement and processing simultaneously. The biggest advantage of the APW 5-Axis Waterjet Cutting System, compared to the ordinary waterjet cutting machine, is that it can realize swing and adjustment of cutting head at random angle, making the preset cutting inclination of the random angle possible. C axis, A axis and the original 3-axis form the 5-axis waterjet cutting system, with rotation angles of A-axis and C-axis at 75 degrees and 360 degrees respectively. The control precision is 0.01mm and the angle control accuracy is 1°as shown in the figure for Z-axis connection.

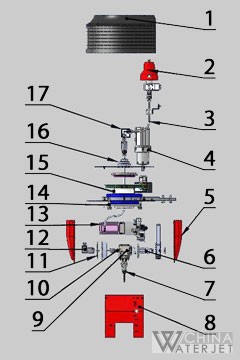

1 – Cover 2 – Water switch 3 – High-voltage tube 4 – Electric motor 5 – 5-Axis side cover 6 – Rotation axis 02 7 – Cutting section 8 – 5-Axis cutting head 9 – 5-Axis cutting head body 10 – Plug screw 11 – Transition set 12 – Fittings body 13 – Electric motor 14 – Junction plate 15 – Rotation axis 16 – Upper dust cover 17 – Two-way connection