4-Axis Waterjet Cutting System

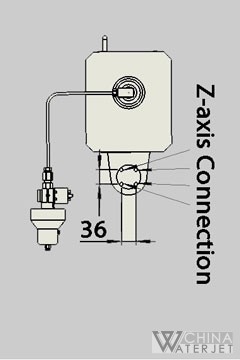

High pressure water switch can quickly shut off high pressure water to save energy. High pressure water can get into cutting head through high pressure pipe, and then get into high precision cutting head body through gem nozzle. Abrasive can get into high precision cutting head body through abrasive transport pipe. Abrasive-water mixture is sprayed onto the materials to be processed through abrasive pipe for cutting purposes. APW 4-Axis Waterjet Cutting System is mainly adopted to conduct slope compensation in the process of cutting, so that the incision can be made completely vertical in shape. APW 4-axis waterjet cutting system has been adopted and achieved good results in many cutting areas, and the most beneficial aspect is that it has a significant decline in processing costs and a great enhancement in processing efficiency. APW 4-axis waterjet cutting system is also a 5-axis structure actually, as one of the axes is manual axis, namely the angle axis. The other is the rotary axis, and the rest are the original three axes. That’s why it is called as 4-axis waterjet cutting system. Since it is 5-axis structure, it can be used without doubt to complete the work set for a 5-axis machine. However, compared to the 5-axis cutting head used in a cutting machine, it has some limitation which is considered to cause small tilt angle. The maximum tilt angle is 45 degrees, and the angle precision of the rotation axis is 0.01 degrees. Due to the angle compensation, the distance between cutting head and cutting material should be very accurate. The height positioning accuracy of the four axes should be 0.01mm and the overall cutting accuracy should be 0.1mm, so as to meet all kinds of cutting requirements. Manual axis is used for angle adjustment with no involvement in linkage. Cutting head interface is connected to Z axis as shown in the figure.

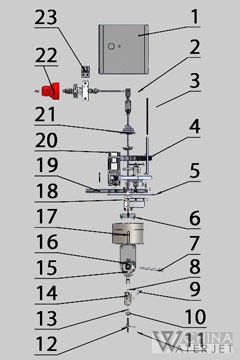

1 – Outer cover 2 – Fittings body 3 – 4-axis door 4 – Door edge 5 – Baffle 6 – Cutter head transition bracket 7 – Lock bolt 8 – Water nozzle 9 – Sand transport pipe joint 10 – Alloy pipe 11 – Sandpipe 12 – Dust cover 13 – Locknut 14 – High precision cutter head body 15 – Cutter head extension rod 16 – Cutter head body 17 – Lower trim cover 18 – Rotary bearing 19 – Upper bottom plate 20 – Electric motor 21 – Upper dust cover 22 – Water switch 23 – 4-axis tube bracket