3-Axis Waterjet Cutting System

Basic Principles of APW 3-Axis Waterjet Cutting System

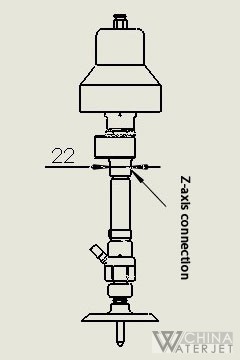

High pressure water switch can quickly shut off high pressure water to save energy. It can get into cutting head through water switch screw bracket, and then get into cutting head body through gem nozzle. Abrasive can get into cutting head body through abrasive transport pipe joint. After abrasive and water are mixed inside the cutting head body, it can be sprayed onto the materials to be processed through abrasive pipe for parts cutting purpose. Parts are connected tightly and accurately through screw thread for easy disassembly and replacement. Cutting head is connected with cutting head bracket through valve body and is fixed to Z axis.

1 – Push-in screw 2 – Cylinder piston rod 3 – Cylinder head 4 – Water switch plug bracket 5 – Alloy pipe 6 – Abrasive transport pipe joint 7 – Pinch nut 8 – Abrasive pipe 9 – Cutting dust cover 10 – Locknut 11 – Cutting head body 12 – Water nozzle 13 – Extension tube 14 – Valve body 15 – Piston