Automatic Abrasive Supply System

Adopted by air pressure abrasive supply mode, APW Automatic Abrasive Supply System is to transmit grinding materials from abrasive supply tank to abrasive storage tank above waterjet cutting head, and then put abrasive into the cutting head under the action of subatmospheric pressure of high pressure water and through abrasive transport pipe, so as to maintain continuous abrasive supply in the waterjet cutting process. When high voltage generator is opened, the magnetic valve of abrasive supply tank will be opened automatically, so that the air flow can get into the tank. When the abrasive level is lower than the inferior limit inside the abrasive tank, an automatic sound and light alarm will be made to remind the operator to add the abrasive.

Filter pressure reducing valve is used to adjust intake flow and maintain pressure inside the abrasive tank between 0.2 and 0.3MPa. Sensor is used to monitor the changes of abrasive level. When the abrasive level is lower than the inferior limit inside the tank, the switching signal is generated.

The main function of APW Automatic Abrasive Supply System is to realize automatic abrasive supply, abrasive shortage alarm and others. It is simple in structure and easy for operation and maintenance. It is considered as the auxiliary equipment to improve the efficiency of waterjet cutting machine.

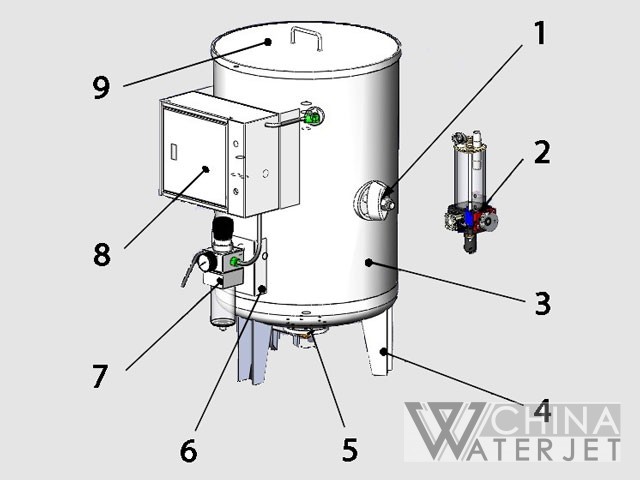

1 – Fixed block 2 – Abrasive control valve kit 3 – Abrasive tank 4 – Stand bar 5 – Abrasive conveyer 6 – Pneumatic triplet fixation plate 7 – Filter pressure reducing valve 8 – Electric box 9 – Abrasive tank cover