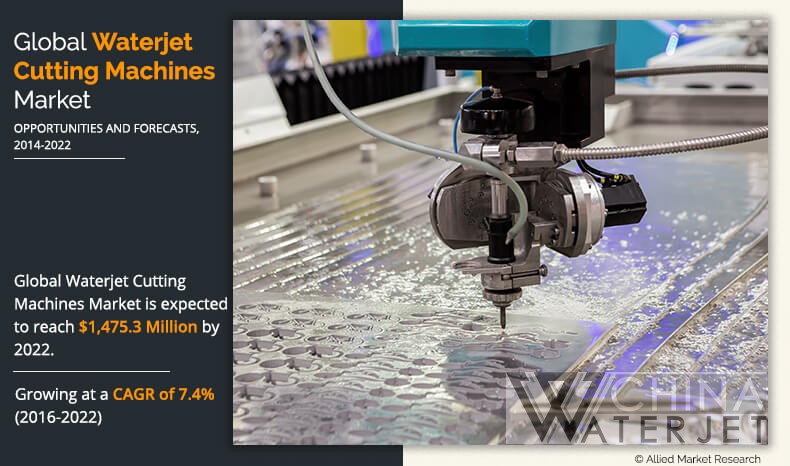

Waterjet Cutting Machines are used to cut a wide array of materials using high pressure water cutting or mixture of abrasive and water. These are used to cut materials such as paper, textile, metal, stone, granite, and others. These machines find applications in automotive, electronics, aerospace, textile, food, construction, mining industries, and others. In the automotive sector, these machines are used for cutting steel, titanium, and other metals, as well as headliners, carpets, and door panels. These are used in the production of metal gaskets for antique automobiles, clutch, brake disks, and other components for racing cars, custom vehicle bodies, and intricate decorative fittings & brackets. These machines have applications in a variety of tasks in the electronics sector such as cutting & designing of circuit boards, electrical enclosures, control panels, components for generators, and other similar equipment. The introduction of advanced technologies, such as multi axis waterjet cutting as well as 3D cutting, would ease the waterjet cutting process to increase its penetration, worldwide. Newer innovations, such as micro waterjet cutting and nanojet cutting, would supplement the growth of the global waterjet cutting machine market. Market players have developed waterjet cutting machines at low prices to cater to the needs of a wider customer base.

The leading players profiled in the report include VICHOR Machinery Co. Limited, WARDJet, Inc, Bystronic Laser AG, Colfax Corporation, OMAX Corporation, Jet Edge, Inc., Resato International BV, Koike Aronson, Inc., Shape Technologies Group, and Hypertherm, Inc.

Five-axis waterjet cutting technology is a gateway to new fabricating opportunities.

While five-axis operations such as bevel cutting and other weld prep operations have been possible on abrasive waterjet machines for some time, the capability to process 3-D parts such as tubes and pipes on the same waterjet is relatively new. This is opening up new possibilities for metal fabricators.

The Global Waterjet Machine Market 2015-2019 research report says enhanced R&D innovations are expected to reduce costs in the worldwide waterjet machine market seeing customers other than traditional end-users generating demand.

Complete report on waterjet machine market spread across 53 pages, providing analysis and profiles of key companies of the industry and supported with 18 exhibits.

Waterjet nozzle technology has advanced to the point where the cutting of parts and part features smaller than 0.012 in. is now possible.

Metal fabricators, like all manufacturers, are seeing growing demand for smaller parts and assemblies required for compact, lighter, energy-efficient products. Abrasive water jet machining is evolving to assist in producing these types of microsize parts.

VICHOR announced “BEST WATERJET PROMO EVER”!

Today VICHOR Waterjet, top one in China waterjet cutting market, announced “BEST WATERJET PROMO EVER“!

Once you have ordered any VICHOR Waterjet, you can get…

High quality show convinces visitors and exhibitors – More exhibitors from abroad

AMB China 2014 covered an area of nearly 24,000 m2 in hall E and hall F in the Nanjing International Expo Centre, a great improvement compared with last year´s event. The exhibition attracted 257 enterprises, which is a 41% increase compared with the 182 exhibitors of last year.

March 31 – April 2, 2014, Asia leading cleaning industry ceremony – the 15th China Clean Expo was successfully held in Shanghai World Expo Exhibition & Convention Center.